- All

- Medical

- Watchmaking

- Luxury

- Aerospace

- Other industries

Field of activity

- All

- Grinding

- Lapping

- Felt polishing

- Brushing

- Brightening

- Carding

- Smoothing

- Satin-finishing

- Polishing

- Milling

- Emery polishing

- Deburring

- Decor

- Drilling

- Electrolytic polishing

Operations

- All

- RECO

- BULA

- SWIS

Brands

- Reset

Field of activity

Operations

Brands

New

MS320

Circular satin-finishing machine

- 4 axis cinematics

- High performance machine

- Complete protection of the mechanical components (covers, bellows and over-pressurization)

New

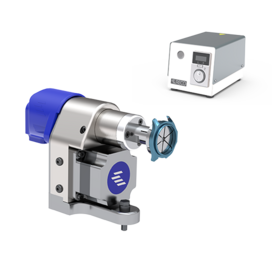

AT340

Electric Bobino, Finishing Accessory

- Silent

- Safe unclamping

- Modular range

New

BU200-UR+

UR-compatible finishing equipment range

- Create your own robotized surface finishing cell

- Universal Robots-compatible range of finishing equipment

- Unequalled modularity, simplified integration, and intuitive control software

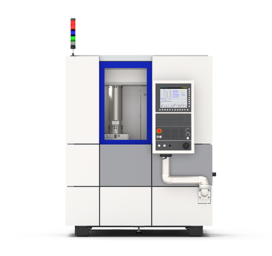

CT501

Compact CNC finishing centre

- 6 digital axes 5 of which are simultaneous

- High rigidity enables hard materials to be machined

- Tool spindle 18'000 rpm

New

POLIGO B1

CNC Polishing, deburring and brushing machine

- 1 CNC work unit

- Machine configuration according to your requirements

- Precision, repeatability and user-friendliness

DLyte Compact

Electrolytic polishing machines

- Based on DryLyte dry electrochemistry technology

- Retains the geometry of the parts

- 3 sizes of machine adapted to the dimensions of the workpieces to be treated

DLyte 100PRO Carbide

Electrolytic polishing machine

- Compact machine, specially designed for cemented carbide

- Automated, high-precision surface treatment

- Suitable for milling cutters, inserts, and other cutting tools

POLIGO B2-M

Advanced deburring machines

- 2 CNC units allowing simultaneous execution of different operations

- Precision, repeatability, and user-friendliness

- Simplified programming via the user interface

POLIGO B3-M

Advanced deburring machines

- 3 CNC units allowing simultaneous execution of different operations

- Precision, repeatability, and user-friendliness

- Simplified programming via the user interface

ML100

Manual lapping machine

- Highly modular thanks to the W20 interface and the design of the tooling support

- Machine offered with adjustable feet or on one of our range of BP workbenches

- Compatible with BU200 series disks and some accessories

Dlyte Desktop Dental | Dlyte Desktop PRO

Electrolytic polishing machine

- Based on DryLyte dry electrochemistry technology

- Retains the geometry of the parts

- User-friendly user interface

MS220

Circular satin-finishing machine

- 4 axis cinematics

- High performance machine

- Complete protection of the mechanical components (covers, bellows and over-pressurization)

CT5

Ultra-compact, environmentally friendly CNC finishing centre

- Sturdy design

- Optimized chip removal

- 5 axis cinematics

BP150

Polishing bench

- Choice of working position with electric height adjustment (optional electric feet)

- Quick access to the dust filter for easy maintenance (Standard size filters)

- Air suction with integrated frequency converter as standard

POLIGO B2

CNC Polishing, deburring and brushing machine

- 2 CNC units allowing simultaneous execution of different operations

- Machine configuration according to your requirements

- Precision, repeatability, productivity and user-friendliness

DLyte PRO500

Electrolytic polishing machine

- Based on DryLyte dry electrochemistry technology

- Retains the geometry of the parts

- Designed for production in large series

MR430

CNC grinding and lapping machine

- 5 digital axes 4 of which are simultaneous

- Fast operation, reducing cycle times

- High rigidity enables hard materials to be machined

MR401

CNC grinding machine

- 4 simultaneous digital axes

- Double tool spindle for machining between lugs and watch case sides simultaneously

- Spring bar hole drilling

POLIGO B3

CNC Polishing, deburring and brushing machine

- 3 to 5 CNC units for carrying out different operations simultaneously

- Machine configuration according to your requirements

- High rates can be achieved

MS300/310

CNC satin finishing machine

- 4 or 5 numerical axes according to model

- Device with 2 orientable abrasive belts

- Extremely compact volume and dimensions of the machine

BP300

Polishing bench

- Choice of working position with electric height adjustment (optional electric feet)

- Quick access to the dust filter for easy maintenance (Standard size filters)

- Optimisation of space thanks to perfect interlocking benches

MP304

Automatic polishing, deburring & brushing machine with rotating table

- Compact monobloc machine equipped with 4 work units

- Production can reach up to 1,800 workpieces/hour

- Programmable rotating table equipped with 12 or 18 workpiece holder spindles

microL

Smoothing and deburring machine

- Replaces tedious manual operation

- Easy to use

- Unequalled productivity - quality ratio

microB range

CNC belt grinding and satin-finishing machines

- MicroB: material removal by absolute dimension control of apply force of the controlled pad

- MicroB-CNC: control of material removal or absolute dimension through a numerical axis

- MicroB-S: Decorative finish "lengthwise satin finishing" or "straight graining"

microP

Automatic polishing, deburring & brushing machine with rotating table

- Ergonomic work station

- Workpieces loaded in concurrent time

- Simplified application of polishing compound controlled by MMI or by operator

BU200

Manual finishing machine

- High precision spindle with Schaublin type W20 collet

- Manually adjustable feeding speed

- Premier quality mechanical and electrical components

BU210

Manual finishing machine

- Manual or semi-automatic work modes

- High precision spindle with Schaublin type W20 collet

- Feeding speed adjustable manually or automatically with pre-programmed cycles

microC

Automatic brush carding machine

- Carding with no risk of injury to the operators in a dust-free environment

- Uniform and regular brush preparation

- Various carding tools available

MR360

Grinding machine

- Digital Z axis with linear motor force-controlled during machining, to avoid chipping

- With 3 linear axes and 1 rotary axis with manual adjustment

- 2 versions of tool spindle, 19'500 or 60'000 rpm

Machines d'occasions

Découvrez aussi nos machines reconditionnées des marques RECO et BULA

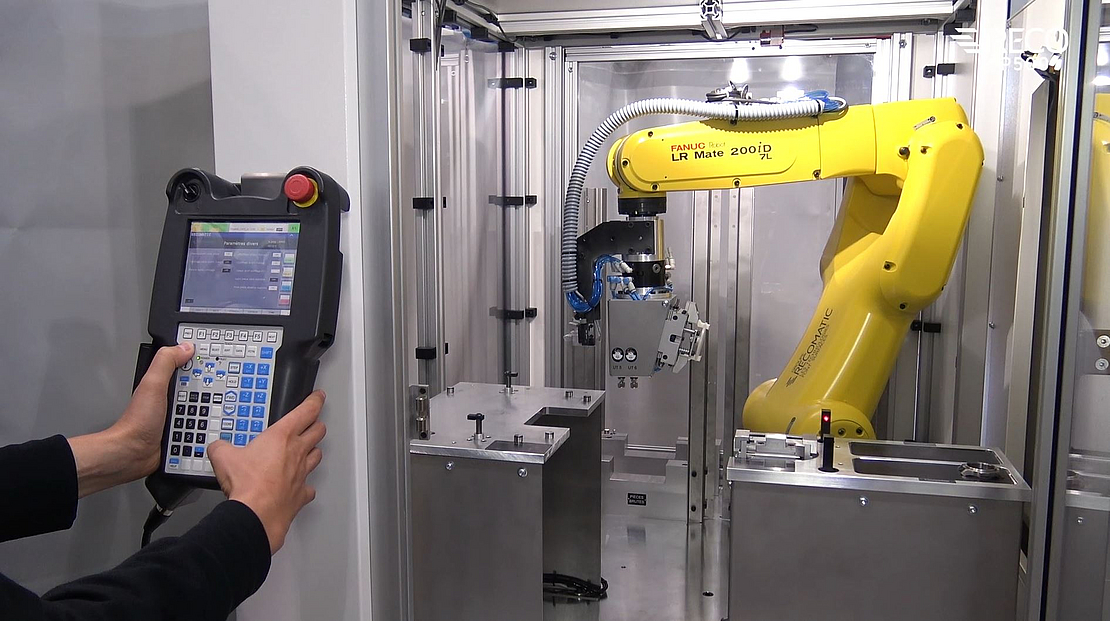

Nos solutions d'automation

Augmentez la productivité et l’autonomie de vos machines RECO et BULA